Molecular Extractions LLC. – Washington State Licensed Producer – Processor: With over 20 years operating experience in extractions & production. Our team of concentrate masters, R & D, along with the leading Manufacturer of Cannabis Extraction “DECIMAL ENGINEERING” allows us to bring you one the most advanced Super Critical Co2 available.

We are experts in the operation of:

We offer Consulting for:

What We Sale:

We can provide you with the Cleanest and Highest Yields for your Money.

CO2 Extraction: also known as Sub Critical Carbon Dioxide Extraction/Super Critical Carbon Dioxide Extraction, is a widely used method in the botanical extraction industry.

It has gained popularity due to its effectiveness in extracting active compounds from a variety of materials, including hemp biomass and botanical material.

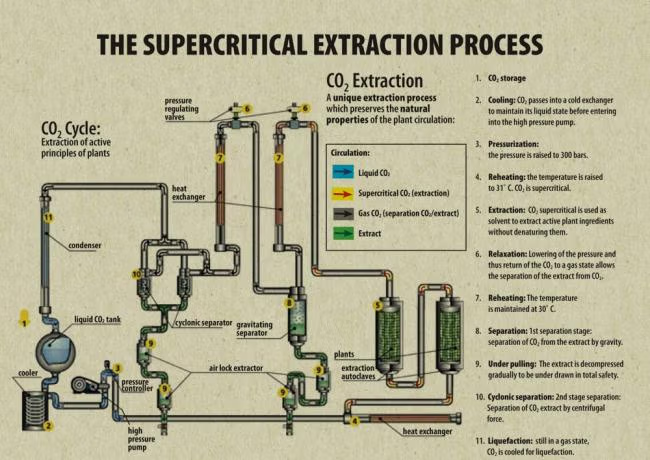

Unlike other extraction methods, CO2 extraction uses carbon dioxide in its supercritical state, where it has both liquid and gas properties, allowing for a highly efficient extraction process.

This method is preferred as it offers many benefits, such as faster extractions, selective extraction of compounds, and the ability to produce high-quality extracts without residual solvents.

CO2 extraction machines play a crucial role in this process by utilizing Diaphragm Compressor Technology, Vacuum Ovens, and other cutting-edge equipment to ensure optimal performance.

With its ability to process a wide range of materials and produce solventless extracts, CO2 extraction has become the go-to option for many industries, including the cannabis industry.

Sub/Super Critical Co2 acts like a lipophilic solvent and can carry lipophilic (oil-loving) plant material such as volatile molecules:

Depending on the plant material, Extraction Conditions, CO2 extracts contain the same components as fixed plant oils (carrier oils), conventional extracts or volatile oils (essential oils).

Carbon Dioxide (CO2) used as a solvent for extraction is a safe, clean, renewable, and very effective method for extracting a wide range of botanicals for an even broader range of products in the medicinal, pharmaceutical, nutraceutical, aromatic, and food industries.

Co2 is inert (no scent or color), is non-toxic, has GRAS status (meaning it is Generally Recognized As Safe under FDA rules), and is affordable and available.

CO2 has the ability to behave like a fluid when compressed under certain conditions.

Acting like a fluid, it can dissolve non-polar material with a low molecular weight in a process known as Supercritical Fluid extraction (SCF).

The advantages of this method of extraction to conventional extractions and pressing are:

CO2 extraction, also known as supercritical carbon dioxide extraction, is a widely used method in the botanical extraction industry. It has gained popularity due to its effectiveness in extracting active compounds from a variety of materials, including hemp biomass and botanical material. Unlike other extraction methods, CO2 extraction uses carbon dioxide in its supercritical state, where it has both liquid and gas properties, allowing for a highly efficient extraction process. This method is preferred as it offers many benefits, such as faster extractions, selective extraction of compounds, and the ability to produce high-quality extracts without residual solvents. CO2 extraction machines play a crucial role in this process by utilizing diaphragm compressor technology, vacuum ovens, and other cutting-edge equipment to ensure optimal performance. With its ability to process a wide range of materials and produce solventless extracts, CO2 extraction has become the go-to option for many industries, including the cannabis industry.

Homeopathic Medicine is a traditional system of healthcare that uses plants or plant extracts to treat and prevent various diseases. It is a natural form of medicine that has been used for centuries in various cultures around the world. Herbal extracts are concentrated forms of plant material that are made by extracting the active ingredients from the plant using a solvent. These extracts are used in various forms such as tinctures, oils, capsules, and ointments.

Cannabis is a plant that is grown for its psychoactive and medicinal properties. The plant contains a number of chemical compounds known as cannabinoids, the most well-known of which is cannabidiol (CBD) and tetrahydrocannabinol (THC). Extraction is a used to isolate and concentrate the desired compounds from the cannabis plant. Interest in cannabis extraction and, by extension, in cannabis extraction equipment was rising from earlier as countries legalized its medical and recreational variants.

Cannabidiol (CBD) is the cannabinoid (compound in cannabis) of most interest due to its healing and non-psychoactive properties. This naturally raises interest in CBD extraction technologies such as cryogenic ethanol extraction and CO2 Extraction. However, full spectrum cannabis extracts that also contain other cannabinoids and non-cannabinoids deliver best results due to synergic impact called “entourage effect”.

Cosmetic products are complex mixtures of ingredients with different physical, chemical and functional properties formulated in order to obtain the product with desired activity and quality. Cosmetic product manufacturers can now move from synthetic to plant- based ingredients (also known as ingredients of plant-origin) in order to increase product purity and quality, with the use of the novel Supercritical Fluid CO2 Extraction (SCFE).

Supercritical Fluid CO2 Extraction is a promising extraction technique that helps replace the organic toxic solvents previously in use in the industry (such as chloroform, dichloromethane, diethyl ether, methanol etc.).

Due to its unique properties, the desirable texture, absence of water or solvent traces, chemical stability and presence of bioactive agents, SCFE extracts can be easily incorporated into cosmetic products. Moreover, SCFE provides a high concentration of bioactive compounds which exhibit many bioactivities in cosmetic products, such as antioxidants, anti-ageing, photo-protective agents or providing antibacterial activity.

SCFE is an environmentally friendly extraction technique based on the application of generally regarded as safe (GRAS) solvent CO2 and high pressures which has many advantages over the conventional processes.

Herbs and spices are very powerful ingredients for cooking or even health. They also provide powerful health benefits like antioxidants, vitamins, and health compounds.As consumer preference shifts towards products with natural ingredients and organic flavors, spice extraction will become a viable solution to meet the increasing demand for spices across the food and beverage, pharmaceutical, nutraceutical, and personal care industries.

Oleoresins are concentrated natural extracts with active compounds from plants, spices and herbs. These are 5-20 times stronger in flavor than their corresponding spices. During their extraction, fewer low flavor notes are destroyed as opposed to during steam distillation of essential oils.

Moreover, oleoresin oils contain some important flavor notes which are absent in volatile oils. For instance, while black pepper oil contains just the top black pepper notes, its oleoresin contains piperine and other low flavor notes, making it a more effective flavoring agent. Oleoresins are used at 0.1-0.5% in finished products.

Consequently, food and spices companies are inclining towards oleoresin production, thus heightening market growth prospects in the forthcoming decade’s forecast period..

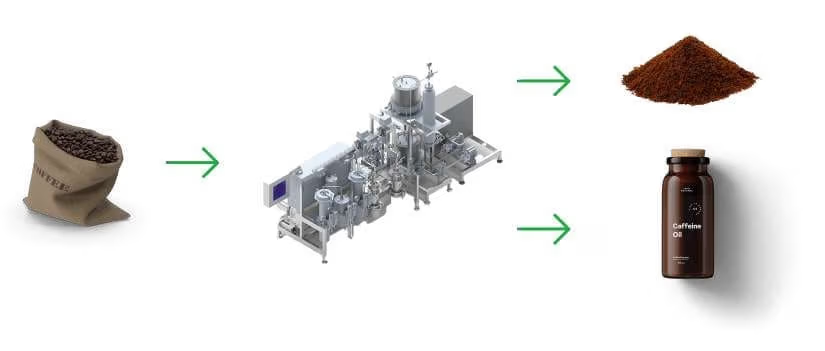

The food, pharmaceutical and chemical industries has seen an immense demand for coffee extracts. Products containing ‘natural’ caffeine are generally perceived to be healthier than those containing ‘synthetic’ caffeine. Carbon Dioxide (CO2) Super Critical fluid extraction is a viable solution to get ‘natural’ caffeine from coffee, with valuable by-products such as Decaf coffee.

Thinking beyond the beverage allows manufacturers to unlock the full potential of Coffee beans with extracts fetching up to 50x more than the produce.

Extraction using supercritical carbon dioxide is a highly selective process. It only extracts the Caffeine compound and leaves the other flavor precursors (such as carbohydrates and peptides) in the bean, delivering superior quality and yield of products at low pressures and near-room temperature, making it a cost-effective solution in the Coffee Extraction business.

Moreover, SCFE preserves the purity of the ingredients without loss of heat-sensitive and volatile components, and is free of residual solvent and microbial contaminants.